Exploring Carbon Neutrality, Carbon Credits, and CO2 Capture Technologies

What does ‘carbon neutral’ means, let's say at a cold night I started a BBQ. If I am burning 1 kg of coal, approximately 2.5 to 3.5 kg of CO₂ is emitted into the atmosphere. Now, if I plant a tree the very next day, that tree could absorb around 21 kg of CO₂ per year. At this moment, I might say my BBQ dinner was carbon neutral, as the tree I planted would absorb most of the CO₂ released the night before. The same analogy is done in large scale emissions. Carbon neutral is about balancing the carbon we emit with efforts to capture or offset that CO₂. If I can demonstrate that I'm capturing or neutralizing my carbon emissions in some way, then the process can be considered carbon neutral.

For businesses, achieving carbon neutrality involves calculating their total emissions from various sources like exhausts, industrial processes, and energy consumption. Companies can then invest in projects that reduce an equivalent amount of carbon, such as supporting carbon offset initiatives. This might involve switching to renewable energy sources, such as solar or wind, or moving away from fossil fuels to greener alternatives.

Carbon neutral does not mean net zero, it means that my capturing process will offset my emissions.

While the tree-planting analogy works for small-scale emissions, it’s not practical for large industries. The amount of land needed to offset global emissions through trees alone is simply not feasible. However, other innovative decarbonization technologies are emerging, offering hope for industries to achieve meaningful emissions reductions.

What is carbon credit?

To fully grasp the concept of carbon credits, it's essential to first understand the Cap-and-Trade system. This system is a market-based approach designed to limit overall greenhouse gas (GHG) emissions. The cap represents the maximum allowable emissions set by the government or regulatory body for a particular industry or economy. Essentially, the cap sets a limit on the total amount of carbon dioxide (CO₂) that can be emitted into the atmosphere.

Once the cap is established, the trade part of the system comes into play. Governments issue permits or allowances to companies and organizations, which grant them the right to emit a specific amount of CO₂—usually measured in tons. Each permit represents one ton of CO₂ that a company is allowed to emit.

How the Trading System Works

The trading aspect of the system allows companies to buy and sell permits based on their emissions. If a company is able to reduce its emissions through initiatives like switching to renewable fuels, implementing carbon capture and storage (CCS), or adopting other decarbonization technologies, it may find that it doesn't need all of its allotted permits. The company can then sell the extra permits to other companies that are struggling to meet their emission targets.

For example, let's say the government sets a cap on carbon emissions at 140 tons and allocates this total equally between two companies, Company A and Company B. This means each company is given permits to emit 70 tons of CO₂.

Now, if Company A implements decarbonization measures—such as adopting cleaner technologies—and successfully reduces its emissions to 40 tons, it would have 30 tons worth of unused permits. Company A can then sell these extra permits to companies like Company B, which might not have been able to reduce its emissions as effectively. By purchasing the additional permits, Company B can avoid penalties or carbon taxes for exceeding its emission limit.

This transaction occurs in the carbon credit market, where companies that reduce their emissions below the cap can profit by selling their surplus permits, while those that exceed their limits can purchase credits to comply with the regulations

Carbon Capture and Storage (CCS)

CCS is a crucial technology for mitigating the impact of industrial processes that release CO₂ into the atmosphere. There are three main types of CO₂ storage systems that can be applied to various industries, helping reduce greenhouse gas emissions. These systems are:

1. Post-Combustion Capture

2. Pre-Combustion Capture

3. Capture by Oxy-Fuel Combustion, where fuel is burned in oxygen rather than air to exclude nitrogen. In this section, we will explore each type of capture method in general.

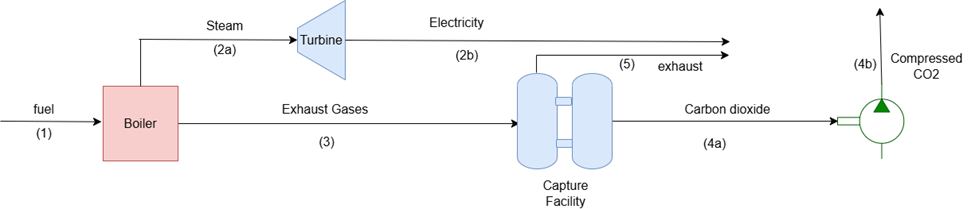

Post-Combustion Capture:

The primary goal of post-combustion capture is to capture CO₂ after it has been emitted during the combustion process. One of the main advantages of this method is that it does not require significant modifications to the existing power plant design.

In this process, whether the fuel used is natural gas, coal, or another type, the fuel is typically burned in a boiler to produce high-pressure steam (Figure 1, Stream 2a), which drives the turbine. Instead of allowing the exhaust gases to be directly released into the atmosphere, the gases are directed to a capture facility through (Figure 1 Stream (3)). Exhaust gases leaving the boiler contain CO₂, nitrogen, excess hydrogen, and water vapor. The capture system filters out the nitrogen, oxygen, and water, leaving behind concentrated CO₂ (Figure 1, stream 5), which is then sent to the plant’s exhaust. The captured CO₂ (Figure 1, Stream 4a) is then compressed and transported to a geological suitable location (Figure 1, stream 4b), typically located in deep underground production wells, where it is stored securely.

In this capture facility, CO₂ is separated from the other gases using solvents, typically an amine solvent diluted in water.

One of the major challenges of post-combustion capture is its high energy demand. Capturing 100% of CO₂ is extremely energy-intensive, so typically only 80-90% of the CO₂ is captured, making the process more energy-efficient while still significantly reducing emissions.

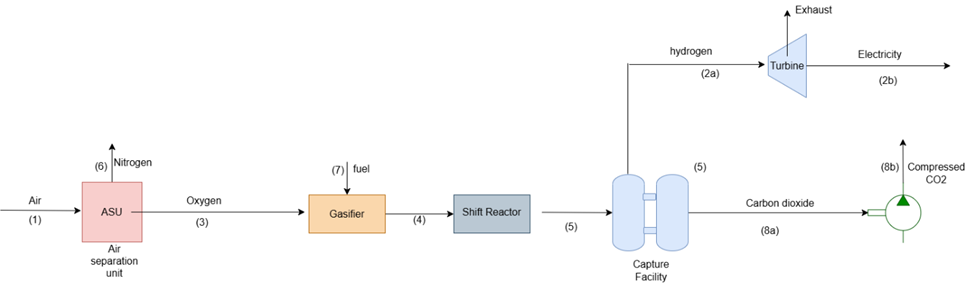

Pre-Combustion Capture:

While post-combustion capture involves capturing carbon dioxide after combustion, pre-combustion capture, as the name suggests, focuses on capturing the exhaust gases before combustion occurs. One advantage of this process is that it produces hydrogen, which can be utilized in a gas turbine to generate electricity. The hydrogen produced in a pre-combustion facility is commonly referred to as 'blue hydrogen.'

This process follows specific and distinct steps that differ significantly from conventional power plant operations, making it suitable for newly constructed plants, where the decision to use pre-combustion capture will be decided in the design phase of the project. The solid fuel is sent to what is known as a gasifier to convert it to hydrogen and carbon monoxide. However, if the fuel used is gaseous, such as natural gas, this step is referred as reforming and not a gasifier. Typically, for pre-combustion capture autothermal reforming unit (ATR) is used commonly.

In downstream facilities, hydrogen is produced through steam methane reforming (SMR) unit. ATR is distinct from SMR in that it uses both oxygen and steam rather than only steam. The choice of reforming method for pre-combustion whether SMR or ATR is used depends on the specific application needed.

Process:

1. Air Separation Unit (ASU): Air enters the air separation unit (Figure 2, stream 1), where oxygen and nitrogen are separated. The goal is to produce high-purity oxygen, which is then fed into the next step of the process—gasification.

2. Gasification: The gasifier reacts the fuel with oxygen and steam to produce synthesis gas (syngas) (Figure 2, stream 4). Syngas is a mixture of hydrogen, carbon monoxide, water, and carbon dioxide.

3. Water-Gas Shift Reaction: In this step, carbon monoxide (CO) reacts with water (H₂O) in the shift reaction, producing more hydrogen (H₂) and carbon dioxide (CO₂):

CO+H2O→CO2 + H₂

4. Capture facility: The gas leaving the shift reaction (Figure 2, stream 5) is then directed to the capture facility. Here, hydrogen is separated for use in the gas turbine to produce electricity, while the carbon dioxide is captured, compressed (Figure 2, stream 8a), and sent to a geological storage site (Figure 2, stream 8b).

In the capture unit, a solvent is used to selectively absorb CO₂ while allowing the hydrogen to pass through. Since nitrogen has already been removed earlier in the process, the capture process becomes more efficient.

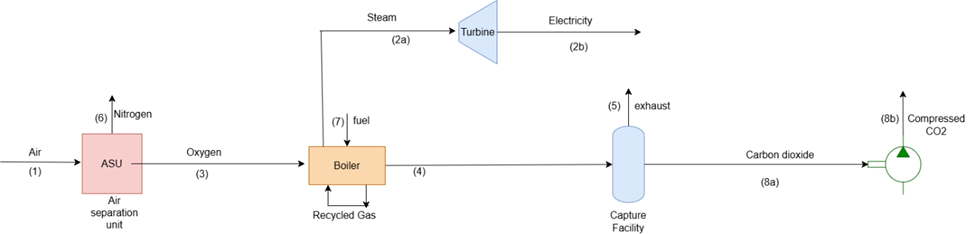

Oxy-Fuel Combustion:

Oxy-fuel combustion is a carbon capture technology that requires the addition of new equipment and modifications to an existing power plant’s boiler to accommodate the oxy-fuel combustion unit. These changes are necessary to ensure the system integrates effectively with the current power plant infrastructure.

The process begins with air entering the Air Separation Unit (ASU), where oxygen is separated from nitrogen. The high-purity oxygen is then fed into the boiler along with the fuel. Since nitrogen has been removed upstream, only oxygen and fuel enter the combustion chamber. Burning the fuel in pure oxygen results in much higher temperatures than traditional air-based combustion. These elevated temperatures can be problematic, as the construction materials of the combustion chamber may not withstand the heat. To address this challenge, part of the exhaust gases from the combustion process is redirected back into the boiler. This dilution of the inlet gas helps control the temperature and prevents the chamber from overheating, with the recycled gases effectively acting as an inert cooling agent.

The Boiler will generate steam (Figure 3, Stream 2a) which drives a steam turbine to produce electricity. In addition of steam, carbon dioxide is also a product of combustion, the (CO₂) from the boiler are sent to a carbon capture facility (Figure 3, Stream 4), where the carbon dioxide (CO₂) is separated, compressed, and transported to a geological storage site for long-term storage.

In the capture facility, the CO₂ is also dried to remove water (Figure 3, Stream 5) through a simple drying process, ensuring the gas is ready for safe and effective storage. This process significantly reduces CO₂ emissions from the power plant, contributing to the overall goal of carbon neutrality.